Motor Introduction

Motors are the workhorses of process plants, powering pumps, fans, compressors, and valves. For engineers, understanding how motors behave is essential to modeling process equipment, selecting actuators, and troubleshooting performance issues.

What is a Motor? ⚙️

A motor converts electrical energy into mechanical rotation.

- DC Motors: Simple, controlled by voltage or current, often used in lab equipment or small actuators.

- AC Induction Motors: Most common in industrial pumps and fans because they are rugged and efficient.

- Stepper / Servo Motors: Used in precise positioning, such as valve actuators.

Torque, Speed, and Power 💡

- Torque (T): Rotational force (N·m).

- Speed (ω): Angular velocity (rad/s or rpm).

- Power (P): `P = T \cdot \omega`

Example: A pump motor provides T = 5 N·m at ω = 100 rad/s.

Motors in Process Control 🏭

- Pumps: Motors drive centrifugal or positive displacement pumps. Flow is proportional to speed. Pressure depends on motor torque and pump curve.

- Valves / Actuators: Motors position valve stems via gearboxes. Control signal → motor movement → valve opening.

- Compressors and Fans: Motor speed directly affects throughput and system pressure.

Control and Dynamics 🔄

Motor behavior introduces dynamics:

- Voltage or frequency input → mechanical rotation (with inertia, delay).

- Starting torque is limited; large loads may cause stalls.

- Speed control often uses Variable Frequency Drives (VFDs) for AC motors or PWM (Pulse Width Modulation) for DC motors.

Common Misunderstandings ❌

- Bigger motor ≠ better → oversizing wastes energy and reduces controllability.

- Voltage does not directly equal speed in AC induction motors → frequency is the key.

- Motors have limits on startup torque; a stuck pump may burn out a motor.

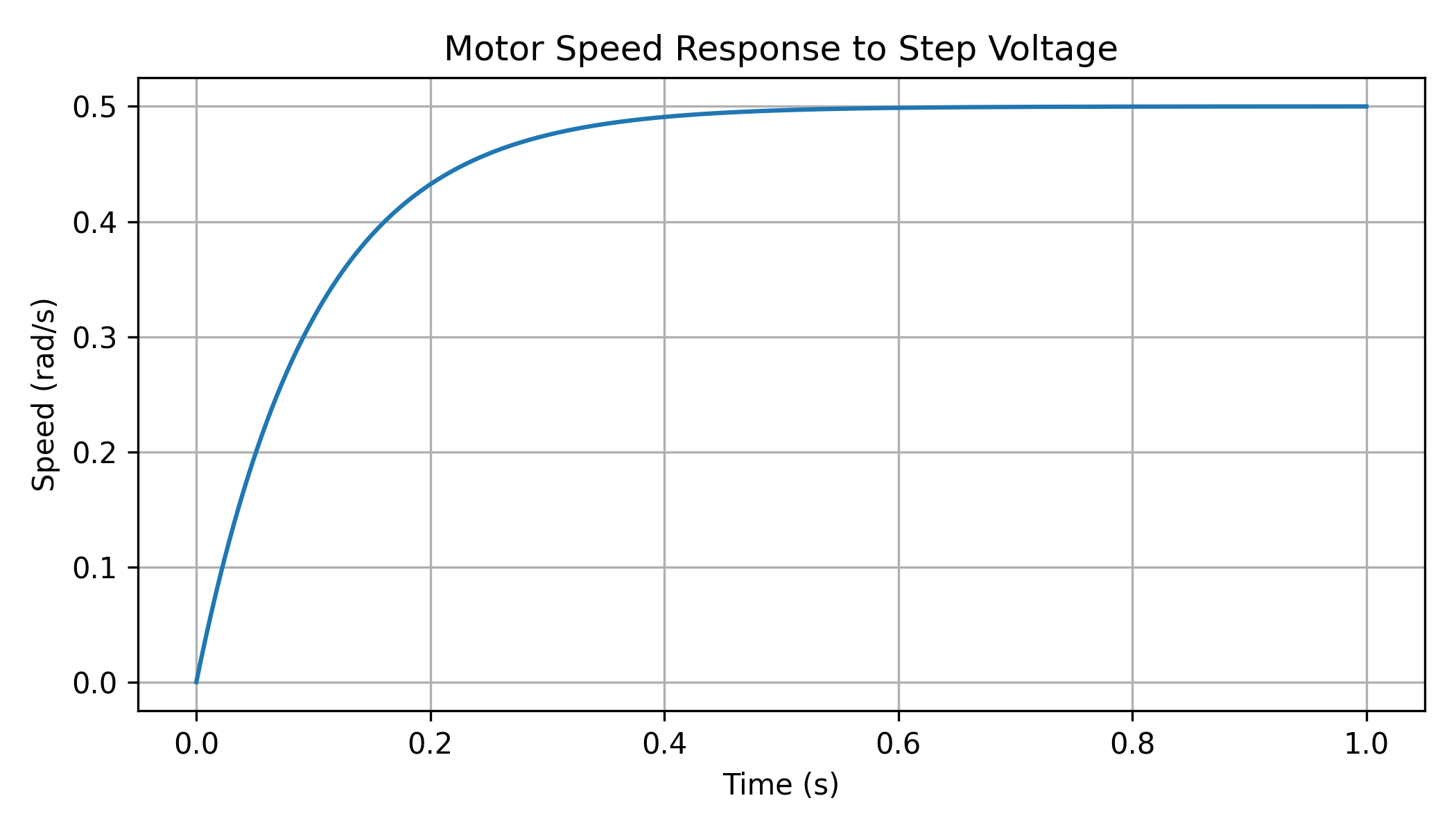

Simulating a Simple Motor Model 📊

import matplotlib.pyplot as plt

# Motor parameters

J = 0.01 # inertia (kg·m^2)

b = 0.1 # damping (N·m·s)

K = 0.01 # motor constant (N·m/A)

R = 1.0 # resistance (ohm)

L = 0.5 # inductance (H)

V = 5 # input voltage (V)

t = np.linspace(0, 1, 500)

omega = (K*V/R) * (1 - np.exp(-(b/J)*t)) / b

plt.figure(figsize=(7,4))

plt.plot(t, omega)

plt.xlabel('Time (s)')

plt.ylabel('Speed (rad/s)')

plt.title('Motor Speed Response to Step Voltage')

plt.grid(); plt.tight_layout()

plt.savefig('motor.png',dpi=300)

plt.show()

Quiz: Motors in Process Control

1. Which variable directly controls the speed of an AC induction motor when using a Variable Frequency Drive (VFD)?

- Incorrect. Voltage affects torque, not speed.

- Correct. Motor synchronous speed is proportional to supply frequency.

- Incorrect. Current affects torque, not speed.

- Incorrect. Resistance is a motor parameter, not a control input.

2. A pump motor stalls on startup. What is the most likely cause?

- Correct. Motors must provide sufficient starting torque to overcome static resistance.

- Incorrect. More voltage usually increases torque, unless protection circuits trip.

- Incorrect. While the pump size matters, the key is torque demand versus motor capability.

- Incorrect. Lower viscosity reduces resistance. This would not cause stalling.

3. In a motor-driven valve actuator, why is precise positioning possible with a stepper motor?

- Incorrect. Speed is not the reason; precision comes from discrete steps.

- Correct. Each pulse corresponds to a small angular movement, allowing precise control.

- Incorrect. This does not explain precise positioning.

- Incorrect. Steppers are precise, but often lower torque.

Exercise (20–30 min): Motor Selection for a Pump

An engineer must select a motor for a pump that requires:

- Flowrate proportional to speed (Q ∝ ω)

- Pressure proportional to square of speed (ΔP ∝ ω²)

- Shaft torque demand: `T_{load} = 0.05 \omega` (with ω in rad/s, T in N·m)

- Target operating speed: ω = 100 rad/s

Tasks:

- Calculate the required torque and power at target speed.

- Suggest whether a DC motor or an AC induction motor with VFD is more appropriate for plant-scale operation.

- Sketch how you would integrate this motor into a feedback control loop (Motor + Pump + Flow Sensor + Controller).

Solution

Required torque at `\omega = 100 \text{rad/s}` is `T_{load} = 0.05 \cdot 100 = 5 \text{N·m}`.

Power is `P = T \cdot \omega = 5 \times 100 = 500 \text{W}`.

Include a design margin (e.g., 20–30%) for transients and uncertainties and select a motor rated ≈ 0.75–1.0 kW depending on duty and service factor.

Recommendation: For plant-scale pumps, an AC induction motor with a VFD is typically preferred due to robustness, standardization, and efficient variable-speed operation. DC motors are fine for labs/smaller systems but require more maintenance (brushes/commutation).

Control Integration Setpoint (flow) → Controller → speed command → VFD → Motor → Pump/Process → Flow Sensor (PV) → back to Controller. Add interlocks (overcurrent, low suction pressure, high discharge pressure) and ramp/anti-windup in the controller for smooth starts/stops.