Level Regulation with MPC

Pumped-storage hydroelectricity is a promising method to improve energy dispatch potential with increasing renewable sources such as wind and solar. The following application is a dual reservoir system with pumped water that either enters the upper or lower reservoir.

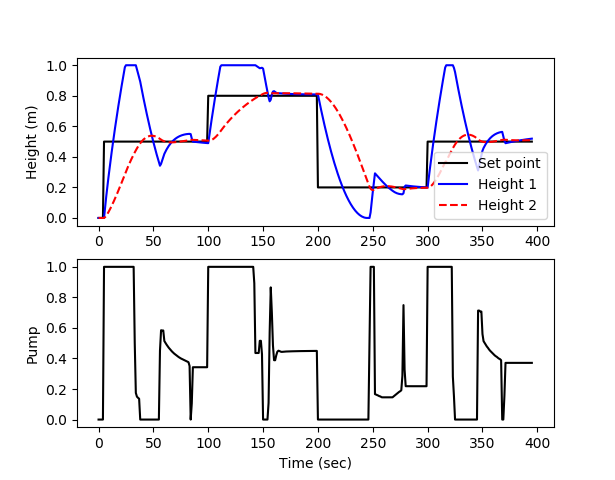

You are asked to develop a model predictive controller (MPC) to reach a level set point for tank 2 (e.g. 50% full, level=0.5), initially starting from empty tanks. Tune the controller for satisfactory performance with setpoint changes in the level or with disturbances to the valve position (`\gamma_1`). Demonstrate the control performance and discuss methods used to achieve satisfactory control during startup from empty and with valve position changes (show both of these).

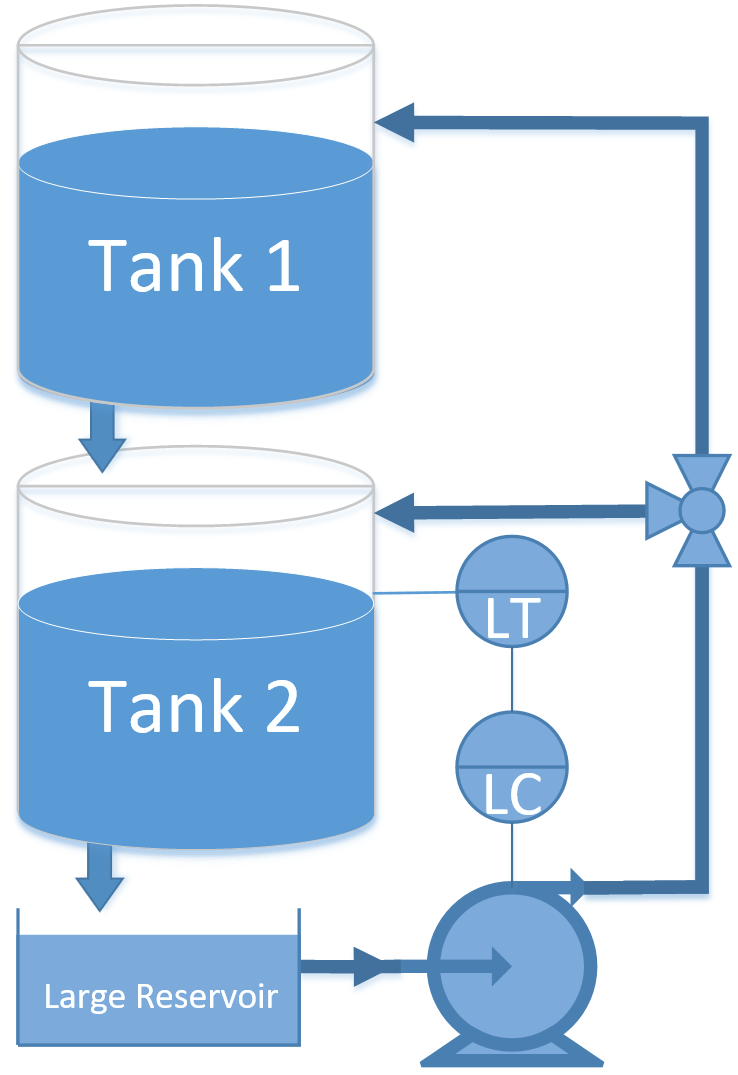

A pump transports water to tank 1 where it drains to tank 2. Both tanks have an opening at the bottom that allows liquid to flow out. A valve is used to divert pumped liquid into tank 1 (valve position=0), into tank 2 (valve position=1) or fractionally into both (valve position 0-1). The valve position is not available to the controller as a measurement and is considered a disturbance to the process. Only the level of tank 2 (bottom tank) is available as a measured value. The pump rate can be manipulated between 0 and 1. The pump has a maximum rate of change of 0.1 every second.

For control you can use linear or nonlinear model predictive control. For estimation, you can use moving horizon estimation (MHE) or simple bias updating. The simplest option is linear MPC with bias updating. The following is a linear second order model that approximates the level dynamics.

$$\tau_{1} \frac{h_1}{dt} = -h_1 + K_1 \, p$$ $$\tau_{2} \frac{h_2}{dt} = -h_2 + K_2 \, h_1$$

where 1 and 2 refer to the tanks, `\tau_1=18.4` and `\tau_2=24.4` are time constants, `K_1=1.3` and `K_2=1.0` are gains, `h_1` and `h_2` are liquid level heights, and p is the pump flow between 0 and 1.

Python (GEKKO Solution)

import matplotlib.pyplot as plt

from scipy.integrate import odeint

import csv

from gekko import GEKKO

# create MPC with GEKKO

m = GEKKO()

m.time = [0,1,2,4,8,12,16,20]

# empirical constants

Kp_h1 = 1.3

tau_h1 = 18.4

Kp_h2 = 1

tau_h2 = 24.4

# manipulated variable

p = m.MV(value=0,lb=1e-5,ub=1)

p.STATUS = 1

p.DCOST = 0.01

p.FSTATUS = 0

# unmeasured state

h1 = m.Var(value=0.0)

# controlled variable

h2 = m.CV(value=0.0)

h2.STATUS = 1

h2.FSTATUS = 1

h2.TAU = 20

h2.TR_INIT = 1

# equations

m.Equation(tau_h1*h1.dt()==-h1 + Kp_h1*p)

m.Equation(tau_h2*h2.dt()==-h2 + Kp_h2*h1)

# options

m.options.IMODE = 6

m.options.CV_TYPE = 2

# simulated system (for measurements)

def tank(levels,t,pump,valve):

h1 = max(1.0e-10,levels[0])

h2 = max(1.0e-10,levels[1])

c1 = 0.08 # inlet valve coefficient

c2 = 0.04 # tank outlet coefficient

dhdt1 = c1 * (1.0-valve) * pump - c2 * np.sqrt(h1)

dhdt2 = c1 * valve * pump + c2 * np.sqrt(h1) - c2 * np.sqrt(h2)

if h1>=1.0 and dhdt1>0.0:

dhdt1 = 0

if h2>=1.0 and dhdt2>0.0:

dhdt2 = 0

dhdt = [dhdt1,dhdt2]

return dhdt

# Initial conditions (levels)

h0 = [0,0]

# Time points to report the solution

tf = 400

t = np.linspace(0,tf,tf+1)

# Set point

sp = np.zeros(tf+1)

sp[5:100] = 0.5

sp[100:200] = 0.8

sp[200:300] = 0.2

sp[300:] = 0.5

# Inputs that can be adjusted

pump = np.zeros(tf+1)

# Disturbance

valve = 0.0

# Record the solution

y = np.zeros((tf+1,2))

y[0,:] = h0

# Create plot

plt.figure(figsize=(10,7))

plt.ion()

plt.show()

# Simulate the tank step test

for i in range(1,tf):

#########################

# MPC ###################

#########################

# measured height

h2.MEAS = y[i,1]

# set point deadband

h2.SPHI = sp[i]+0.01

h2.SPLO = sp[i]-0.01

h2.SP = sp[i]

# solve MPC

m.solve(disp=False)

# retrieve 1st pump new value

pump[i] = p.NEWVAL

#########################

# System ################

#########################

# Specify the pump and valve

inputs = (pump[i],valve)

# Integrate the model

h = odeint(tank,h0,[0,1],inputs)

# Record the result

y[i+1,:] = h[-1,:]

# Reset the initial condition

h0 = h[-1,:]

# update plot every 5 cycles

if (i%5==3):

plt.clf()

plt.subplot(2,1,1)

plt.plot(t[0:i],sp[0:i],'k-')

plt.plot(t[0:i],y[0:i,0],'b-')

plt.plot(t[0:i],y[0:i,1],'r--')

plt.ylabel('Height (m)')

plt.legend(['Set point','Height 1','Height 2'])

plt.subplot(2,1,2)

plt.plot(t[0:i],pump[0:i],'k-')

plt.ylabel('Pump')

plt.xlabel('Time (sec)')

plt.draw()

plt.pause(0.01)

# Construct and save data file

data = np.vstack((t,pump))

data = np.hstack((np.transpose(data),y))

np.savetxt('data.txt',data,delimiter=',')

Python (GEKKO Animated Solution)

import matplotlib.pyplot as plt

from scipy.integrate import odeint

from gekko import GEKKO

from matplotlib.widgets import Button

import time

tf = 200

t_span = np.linspace(0, tf, tf + 1)

valve = 0.0

# Setpoint trajectory

sp = np.ones(tf + 1) *0.5

sp[int(tf/2):] = np.random.choice([0.2, 0.3, 0.4, 0.6, 0.7, 0.8])

# Create plots

scale = 0.5

fig, axs = plt.subplots(3, 2, figsize=(16*scale, 9*scale), sharey='row', gridspec_kw={'width_ratios': [1, 2]})

# Initialize bar plots

tank_1_bar, = axs[0, 0].bar(x = 0, height = 0, width = 1.0, color = 'b', label='Tank 1 Level')

tank_2_bar, = axs[1, 0].bar(x = 0, height = 0, width = 1.0, color = 'b', label='Tank 2 Level')

pump_speed, = axs[2, 0].bar(x = 0, height = 0.5, width = 1.0, facecolor = 'none', edgecolor = 'black', label='Pump speed')

# Initialize line plots

line_y1, = axs[0, 1].plot([], [], 'b-', label='Manual')

line_y1_gekko, = axs[0, 1].plot([], [], 'b--', label='GEKKO MPC')

line_y2, = axs[1, 1].plot([], [], 'r-', label='Manual')

line_y2_gekko, = axs[1, 1].plot([], [], 'r--', label='GEKKO MPC')

line_sp, = axs[1, 1].plot([], [], 'k-', label='Setpoint')

line_pump, = axs[2, 1].plot([], [], 'g-', label='Manual')

line_pump_gekko, = axs[2, 1].plot([], [], 'g--', label='GEKKO MPC')

# Set axes ranges and labels

axs[0, 1].legend()

axs[1, 1].legend()

axs[2, 1].legend()

axs[0, 0].set_ylabel('Tank 1 level')

axs[0, 0].set_xlim(-0.5,0.5)

axs[0, 0].set_ylim(-0.1,1.1)

axs[0, 0].set_title = 'Tank 1 level'

axs[1, 0].set_ylabel('Tank 2 level')

axs[1, 0].set_xlim(-0.5,0.5)

axs[1, 0].set_ylim(-0.1,1.1)

axs[2, 0].set_ylabel('Pump speed')

axs[2, 0].set_xlim(-0.5,0.5)

axs[2, 0].set_ylim(-0.1,1.6)

axs[0, 1].set_xlim(0,tf)

axs[1, 1].set_xlim(0,tf)

axs[2, 1].set_xlim(0,tf)

axs[2, 1].set_xlabel('Time')

# Show the tank and pump limit lines

axs[0,0].plot([-0.5, 0.5], [1.0, 1.0], 'k:')

axs[1,0].plot([-0.5, 0.5], [1.0, 1.0], 'k:')

axs[2,0].plot([-0.5, 0.5], [1.5, 1.5], 'k:')

axs[0,1].plot([0, tf], [1.0, 1.0], 'k:')

axs[1,1].plot([0, tf], [1.0, 1.0], 'k:')

axs[2,1].plot([0, tf], [1.5, 1.5], 'k:')

# Create button axes

ax_increase = plt.axes([0.8, 0.02, 0.1, 0.04])

ax_decrease = plt.axes([0.7, 0.02, 0.1, 0.04])

# Create buttons

btn_increase = Button(ax_increase, 'Pump +0.05')

btn_decrease = Button(ax_decrease, 'Pump -0.05')

plt.ion()

plt.show()

# Simulated system (for measurements)

def tank(levels, t, pump, valve):

h1 = max(1.0e-10, levels[0])

h2 = max(1.0e-10, levels[1])

c1 = 0.08 # inlet valve coefficient

c2 = 0.04 # tank outlet coefficient

dhdt1 = c1 * (1.0 - valve) * pump - c2 * np.sqrt(h1)

dhdt2 = c1 * valve * pump + c2 * np.sqrt(h1) - c2 * np.sqrt(h2)

if h1 >= 1.0 and dhdt1 > 0.0:

dhdt1 = 0

if h2 >= 1.0 and dhdt2 > 0.0:

dhdt2 = 0

return [dhdt1, dhdt2]

def sim():

# Manual simulation loop

current_i = 0

# Initial conditions

h0 = [0, 0]

# Record the solution

y = np.zeros((tf + 1, 2))

y[0, :] = h0

# Initial pump values

current_pump = 0.5 # Initial pump value

pump = np.ones(tf + 1) * current_pump # Initialize pump array

# Button callback functions

def increase_pump(event):

nonlocal current_pump, pump, current_i

current_pump = min(current_pump + 0.05, 1.5)

pump[current_i:] = current_pump

def decrease_pump(event):

nonlocal current_pump, pump, current_i

current_pump = max(current_pump - 0.05, 0.0)

pump[current_i:] = current_pump

# Connect buttons

btn_increase.on_clicked(increase_pump)

btn_decrease.on_clicked(decrease_pump)

for i in range(tf):

current_i = i

# Integrate the model

inputs = (pump[i], valve)

h = odeint(tank, y[i, :], [0, 1], inputs)

# Record the result

y[i + 1, :] = h[-1, :]

# Update bar plot data

tank_1_bar.set_height(y[i + 1, 0])

tank_2_bar.set_height(y[i + 1, 1])

pump_speed.set_height(pump[i])

# Change the bar colors if the tanks overflow

if y[i + 1, 0] < 1.0:

tank_1_bar.set_color('b')

else:

tank_1_bar.set_color('r')

if y[i + 1, 1] < 1.0:

tank_2_bar.set_color('b')

else:

tank_2_bar.set_color('r')

# Update line data

line_sp.set_data(t_span[:i + 1], sp[:i + 1])

line_y1.set_data(t_span[:i + 1], y[:i + 1, 0])

line_y2.set_data(t_span[:i + 1], y[:i + 1, 1])

line_pump.set_data(t_span[:i + 1], pump[:i + 1])

plt.pause(0.015)

# Allow some time adjust the figure area

if i == 0:

plt.pause(5)

## GEKKO MPC Solution ##

# Reset initial conditions

h0 = [0,0]

y = np.zeros((tf+1,2))

y[0,:] = h0

pump = np.zeros(tf+1)

# create MPC with GEKKO

m = GEKKO(remote = False)

m.time = [0, 2, 4, 8, 10, 20]

# empirical constants

Kp_h1 = 1.4

tau_h1 = 18.4

Kp_h2 = 1

tau_h2 = 24.4

# manipulated variable (pump)

p = m.MV(value=0.5,lb=1e-5,ub=1.5)

p.STATUS = 1

p.DCOST = 0.01

p.FSTATUS = 0

# unmeasured state

h1 = m.Var(value=0.0, ub = 0.90)

# controlled variable

h2 = m.CV(value=0.0)

h2.STATUS = 1

h2.FSTATUS = 1

h2.TAU = 20

h2.TR_INIT = 1

# equations

m.Equation(tau_h1*h1.dt()==-h1 + Kp_h1*p)

m.Equation(tau_h2*h2.dt()==-h2 + Kp_h2*h1)

# options

m.options.IMODE = 6

m.options.CV_TYPE = 2

m.options.MV_STEP_HOR = 1

# GEKKO simulation loop

current_i = 0

for i in range(tf):

current_i = i

#########################

# MPC ###################

#########################

# measured height

h2.MEAS = y[i,1]

# set point deadband

h2.SPHI = sp[i]+0.01

h2.SPLO = sp[i]-0.01

h2.SP = sp[i]

# solve MPC

m.solve(disp=False)

# retrieve 1st pump new value

pump[i] = p.NEWVAL

#########################

# System ################

#########################

# Specify the pump and valve

inputs = (pump[i],valve)

# Integrate the model

h = odeint(tank,h0,[0,1],inputs)

# Record the result

y[i+1,:] = h[-1,:]

# Reset the initial condition

h0 = h[-1,:]

# Update bar plot data

tank_1_bar.set_height(y[i + 1, 0])

tank_2_bar.set_height(y[i + 1, 1])

# Change the bar colors if the tanks overflow

if y[i + 1, 0] < 1.0:

tank_1_bar.set_color('b')

else:

tank_1_bar.set_color('r')

if y[i + 1, 1] < 1.0:

tank_2_bar.set_color('b')

else:

tank_2_bar.set_color('r')

pump_speed.set_height(pump[i])

# Update line data

line_y1_gekko.set_data(t_span[:i], y[:i, 0])

line_y2_gekko.set_data(t_span[:i], y[:i, 1])

line_pump_gekko.set_data(t_span[:i], pump[:i])

plt.pause(0.01)

run_sim = True

while run_sim:

sim()

z = input('Run again (Y/N)?')

run_sim = True if z.upper() == 'Y' else False

if run_sim:

# Reset bar plots

tank_1_bar.set_height(0)

tank_2_bar.set_height(0)

pump_speed.set_height(0.5)

# Reset line plots

line_y1.set_data([], [])

line_y1_gekko.set_data([], [])

line_y2.set_data([], [])

line_y2_gekko.set_data([], [])

line_sp.set_data([], [])

line_pump.set_data([], [])

line_pump_gekko.set_data([], [])

The animated MPC solution begins with manual control and then switches to MPC for comparison. Thanks to Vincent Roos for providing the animated MPC solution.