Heat Integration Optimization

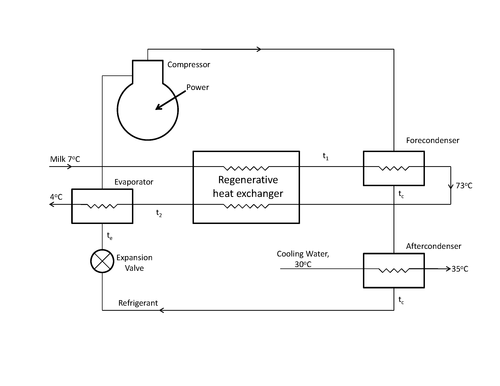

A heat pump is a type of heating and cooling system that uses an external heat source or sink to provide cooling in summer and heating in winter. It can also be used to provide heat for industrial processes such as milk pasteurization. The system works by transferring heat from the source to the milk. The heat exchanger acts as a buffer, to heat the incoming milk and cool the outgoing milk. This type of heat integration is highly efficient and helps to reduce energy costs.

In the pasteurization of milk, the temperature is raised to 73°C, held for 20 sec., and then cooled. The milk arrives at a temperature of 7°C and is delivered from the pasteurizing process for packaging at a temperature of 4°C.

We will consider using a heat pump with a regenerative heat exchanger to do this. One possible cycle is shown in the figure below. The incoming milk is preheated in a regenerative heat exchanger and then heated further in the fore-condenser of the heat pump. As it exits the fore-condenser, the temperature of the milk is 73°C. Thereafter the milk is cooled as it flows through the other side of the regenerative heat exchanger and then through the evaporator of the heat pump.

Find the optimal heat pump and regenerative exchanger that minimizes the total present worth of costs (capital cost and operating cost). Specifically, determine the areas of the heat exchangers (evaporator, condensers, and regenerative exchanger), size of the compressor, and temperatures t1, t2, te and tc that result in the minimum total cost. Run the problem with no constraints on temperatures of approach (Case 1); then rerun with constraints that all temperatures of approach (evaporator, condensers, regenerative heat exchanger) are at least 10 °C (Case 2).

This problem is based on a problem from W. Stoecker, Design of Thermal Systems, 3rd ed.

This assignment can be completed in groups of two. Additional guidelines on individual, collaborative, and group assignments are provided under the Expectations link.

This assignment can be completed in groups of two. Additional guidelines on individual, collaborative, and group assignments are provided under the Expectations link.Solution Help

See GEKKO documentation and additional example problems.

# Initialize Gekko model

m = GEKKO()

# Optimal heat pump and regenerative exchanger that minimizes the total present

# worth of costs (capital cost and operating cost). Specifically, determine the

# areas of the heat exchangers (evaporator, condensers, and regenerative

# exchanger), size of the compressor, and temperatures t1, t2, te and tc

# that result in the minimum total cost

# Parameters

U = 0.6

Ureg = 0.5

mdotm = 4

cpm = 3.75

cpw = 1.00

intrate = 0.09

nper = 6

# Inlet temperature (degC)

ti = 7

# Outlet temperature (degC)

to = 4

# Pasteurization Temperature (degC), target temperature

tp = 73

# Variables

# compressor work (kW)

W = m.Var()

# heat exchanger areas (m^2)

Ae = m.Var(value = 10, lb = 1.0, ub = 1000)

Areg = m.Var(value = 10, lb = 1.0, ub = 1000)

Afc = m.Var(value = 10, lb = 1.0, ub = 1000)

Aac = m.Var(value = 10, lb = 1.0, ub = 1000)

t1 = m.Var(value = ti) # Temperature 1 (degC)

t2 = m.Var(value = ti) # Temperature 2 (degC)

te = m.Var(value = ti) # Evaporator Temperature (degC)

tc = m.Var(value = ti) # Condenser Temperature (degC)

Ctot = m.Var(value = 100000) # Total Cost

# evaporator

Qe = m.Var(value = 1)

dapp1e = m.Var(value = 1)

dapp2e = m.Var(value = 1)

# regenerative heat exchanger

Qreg = m.Var(value = 1)

dapp1reg = m.Var(value = 1)

dapp2reg = m.Var(value = 1)

# fore condenser

Qfc = m.Var(value = 1)

dapp1fc = m.Var(value = 1)

dapp2fc = m.Var(value = 1)

# after condenser

Qac = m.Var(value = 1)

dapp1ac = m.Var(value = 1)

dapp2ac = m.Var(value = 1)

# temps of approach

dappe = m.Var(lb = 0.1) # >= 10

dappc = m.Var(lb = 0.1) # >= 10

dappreg1 = m.Var(lb = 0.1) # >= 10

dappreg2 = m.Var(lb = 0.1) # >= 10

# ratios

ratio_e = m.Var(value = .05, lb = 0.001, ub = 0.999)

ratio_reg = m.Var(value = .05, lb = 0.000, ub = 1.0)

ratio_fc = m.Var(value = .05, lb = 0.001, ub = 0.999)

ratio_ac = m.Var(value = .05, lb = 0.001, ub = 0.999)

# Log-mean temperature differences

delte = m.Var(value = 1)

deltreg = m.Var(value = 1)

deltfc = m.Var(value = 1)

deltac = m.Var(value = 1)

# Coefficient Of Performance

COP = m.Var(value = 1)

# Intermediates

# Cost elec year at 4 hours per day

Celyear= m.Intermediate(W * 4.0 * 365.0 * 0.07)

# Cost total over time

# Multiplier is about 4.5 (instead of 6.0) because of the

# interest rate on unspent capital

mult = m.Intermediate((((1.0+intrate)**nper)-1.0) / (intrate*(1.0+intrate)**nper))

Celtot = m.Intermediate(Celyear * mult)

# Cost equipment

Cequip = m.Intermediate(Ae*200.0 + Afc*200.0 + Aac*200.0 + Areg*200 + W*240.0)

#temperatures in Kelvin

TeK = m.Intermediate(te + 273)

TcK = m.Intermediate(tc + 273)

# Equations

m.Equations([

# Total cost

Ctot == Celtot + Cequip,

# overall energy balance on regen heat exchanger

# mdotm and cpm cancel from each term

t1 + t2 == tp + ti,

# log-mean temperature difference

# lmtd(thi,tco,tho,tci)

# evaporator

Qe == mdotm * cpm *(t2 - to),

dapp1e == to - te,

dapp2e == t2 - te,

# regenerative heat exchanger

Qreg == mdotm * cpm * (tp-t2),

dapp1reg == t2 - ti,

dapp2reg == tp - t1,

# fore condenser

Qfc == mdotm * cpm * (tp - t1),

dapp1fc == tc - tp,

dapp2fc == tc - t1,

# after condenser

Qac == W + mdotm * cpm * (ti - to),

dapp1ac == tc - 35.0,

dapp2ac == tc - 30.0,

# approach temperatures

dappe == to - te, # Temp app evap

dappc == tc - tp, # Temp app fore cond

dappreg1 == t2 - ti, # Temp app reg1

dappreg2 == tp - t1, # Temp app reg2

# ratios

ratio_e * dapp2e == dapp1e,

ratio_reg * dapp2reg == dapp1reg,

ratio_fc * dapp2fc == dapp1fc,

ratio_ac * dapp2ac == dapp1ac,

# Log-mean Temperature Difference

delte * m.log(ratio_e) == (dapp1e - dapp2e),

#deltreg * m.log(ratio_reg) = (dapp1reg - dapp2reg)

deltfc * m.log(ratio_fc) == (dapp1fc - dapp2fc),

deltac * m.log(ratio_ac) == (dapp1ac - dapp2ac),

# Average temperature difference

#delte = (dapp1e + dapp2e) / 2

deltreg == (dapp1reg + dapp2reg) / 2,

#deltfc = (dapp1fc + dapp2fc) / 2

#deltac = (dapp1ac + dapp2ac) / 2

# coefficient of performance

# 75% of Carnot Efficiency

COP * (TcK-TeK) == 0.75 * TeK,

# Work to compressor

W * COP == Qe,

# heat transferred for each exchanger

Ae * U * delte == Qe,

Areg * Ureg * deltreg == Qreg,

Afc * U * deltfc == Qfc,

Aac * U * deltac == Qac

])

# objective function

m.Minimize(Ctot)

# minimize ctot

m.options.SOLVER = 1

m.options.IMODE = 3

m.solve()

print('Minimum cost: ' + str(Ctot[0]))