TCLab PI Control

|  |  |  |

|---|

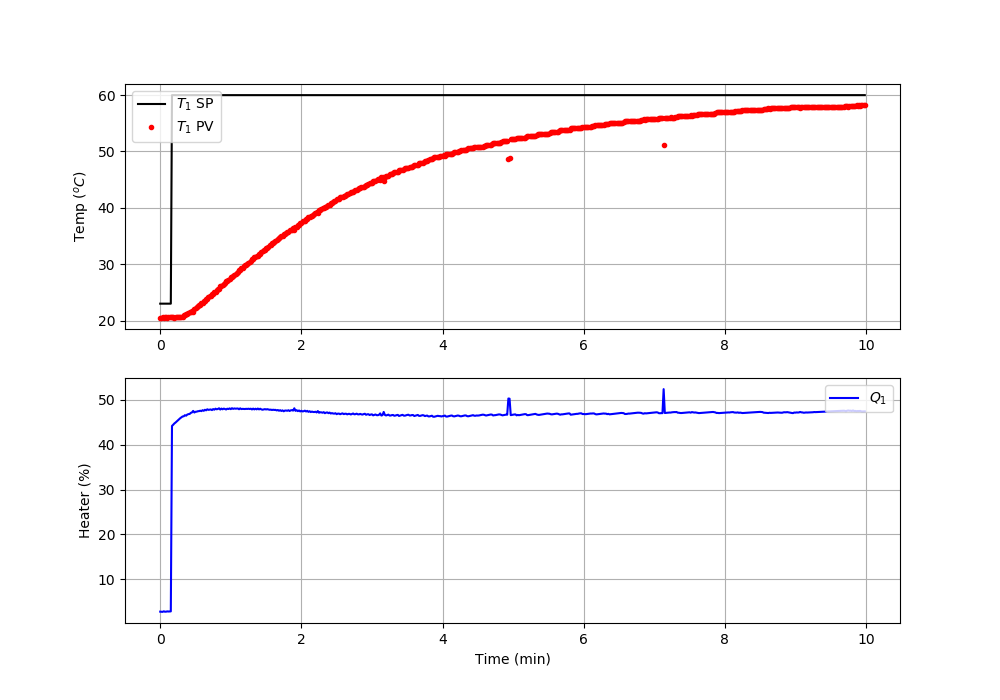

Objective: Implement a discrete PID controller without the derivative term (PI Control). Show the control performance with a setpoint change from 23oC to 60oC.

import matplotlib.pyplot as plt

import tclab

import time

# -----------------------------

# Input controller gain (Kc)

# Input controller time constant (tauI)

# -----------------------------

Kc =

tauI =

n = 600 # Number of second time points (10 min)

tm = np.linspace(0,n-1,n) # Time values

lab = tclab.TCLab()

T1 = np.zeros(n)

Q1 = np.zeros(n)

# step setpoint from 23.0 to 60.0 degC

SP1 = np.ones(n)*23.0

SP1[10:] = 60.0

Q1_bias = 0.0

for i in range(n):

# record measurement

T1[i] = lab.T1

# --------------------------------------------------

# fill-in PI controller equation to change Q1[i]

# --------------------------------------------------

Q1[i] =

# --------------------------------------------------

# implement new heater value with integral anti-reset windup

Q1[i] = max(0,min(100,Q1[i])) # clip to 0-100%

# --------------------------------------------------

lab.Q1(Q1[i])

if i%20==0:

print(' Heater, Temp, Setpoint')

print(f'{Q1[i]:7.2f},{T1[i]:7.2f},{SP1[i]:7.2f}')

# wait for 1 sec

time.sleep(1)

lab.close()

# Save data file

data = np.vstack((tm,Q1,T1,SP1)).T

np.savetxt('PI_control.csv',data,delimiter=',',\

header='Time,Q1,T1,SP1',comments='')

# Create Figure

plt.figure(figsize=(10,7))

ax = plt.subplot(2,1,1)

ax.grid()

plt.plot(tm/60.0,SP1,'k-',label=r'$T_1$ SP')

plt.plot(tm/60.0,T1,'r.',label=r'$T_1$ PV')

plt.ylabel(r'Temp ($^oC$)')

plt.legend(loc=2)

ax = plt.subplot(2,1,2)

ax.grid()

plt.plot(tm/60.0,Q1,'b-',label=r'$Q_1$')

plt.ylabel(r'Heater (%)')

plt.xlabel('Time (min)')

plt.legend(loc=1)

plt.savefig('PI_Control.png')

plt.show()

A proportional integral (PI) controller is a variation of the PID controller without the derivative term. The controller is an equation that adjusts the controller output, `u(t)`, for input into the system as the manipulated variable. It is a calculation of the difference between the setpoint SP and process variable PV. The adjustable parameters are the controller gain, `K_c`, and controller reset time or integral time constant, `\tau_I`. A large gain or small integral time constant produces a controller that reacts aggressively to a difference between the measured PV and target SP.

$$Q(t) = Q_{bias} + K_c \, \left( T_{SP}-T_{PV} \right) + \frac{K_c}{\tau_I}\int_0^t \left( T_{SP}-T_{PV} \right) dt $$

$$\quad = Q_{bias} + K_c \, e(t) + \frac{K_c}{\tau_I}\int_0^t e(t) dt$$

The `Q_{bias}` term is a constant that is typically set to the value of `Q(t)` when the controller is first switched from manual to automatic mode. The deviation variable for the heater is the change in value `Q'(t) = Q(t) - Q_{bias}`. For the TCLab, `Q_{bias}`=0 because the TCLab starts with the heater off. The `Q_{bias}` gives bumpless transfer if the error is zero when the controller is turned on. The error from the set point is the difference between the `T_{SP}` and `T_{PV}` and is defined as `e(t) = T_{SP} - T_{PV}`. The continuous integral is approximated in a discrete form as a summation of the error multiplied by the sample time.

$$\frac{K_c}{\tau_I}\int_0^t e(t) dt \approx \frac{K_c}{\tau_I} \sum_{i=1}^{n_t} e_i(t)\Delta t$$

See additional information on PI controllers. Use a basic tuning correlation with FOPDT parameters (`K_c` and `\tau_p`) determined from the TCLab graphical fitting or TCLab regression exercises.

$$K_c = \frac{1}{K_p} \quad \quad \tau_I = \tau_p$$

Fill in the values of `K_c`, `\tau_I`, and the PI equation in the code below. Add anti-reset windup to prevent the integral from accumulating when the heater is saturated at 0% or 100%.

Solution

import matplotlib.pyplot as plt

import tclab

import time

# -----------------------------

# Input controller gain (Kc)

# Input controller time constant (tauI)

# -----------------------------

Kc = 1/0.9

tauI = 175.0

n = 600 # Number of second time points (10 min)

tm = np.linspace(0,n-1,n) # Time values

lab = tclab.TCLab()

T1 = np.zeros(n)

Q1 = np.zeros(n)

# step setpoint from 23.0 to 60.0 degC

SP1 = np.ones(n)*23.0

SP1[10:] = 60.0

Q1_bias = 0.0

ierr = 0.0

for i in range(n):

# record measurement

T1[i] = lab.T1

# --------------------------------------------------

# fill-in PI controller equation to change Q1[i]

# --------------------------------------------------

err = SP1[i]-T1[i]

ierr += err

Q1[i] = Q1_bias + Kc*err + Kc/tauI * ierr

# --------------------------------------------------

# implement new heater value with integral anti-reset windup

if Q1[i]>=100:

Q1[i]=100

ierr -= err

if Q1[i]<=0:

Q1[i]=0

ierr -= err

# --------------------------------------------------

lab.Q1(Q1[i])

if i%20==0:

print(' Heater, Temp, Setpoint')

print(f'{Q1[i]:7.2f},{T1[i]:7.2f},{SP1[i]:7.2f}')

# wait for 1 sec

time.sleep(1)

lab.close()

# Save data file

data = np.vstack((tm,Q1,T1,SP1)).T

np.savetxt('PI_control.csv',data,delimiter=',',\

header='Time,Q1,T1,SP1',comments='')

# Create Figure

plt.figure(figsize=(10,7))

ax = plt.subplot(2,1,1)

ax.grid()

plt.plot(tm/60.0,SP1,'k-',label=r'$T_1$ SP')

plt.plot(tm/60.0,T1,'r.',label=r'$T_1$ PV')

plt.ylabel(r'Temp ($^oC$)')

plt.legend(loc=2)

ax = plt.subplot(2,1,2)

ax.grid()

plt.plot(tm/60.0,Q1,'b-',label=r'$Q_1$')

plt.ylabel(r'Heater (%)')

plt.xlabel('Time (min)')

plt.legend(loc=1)

plt.savefig('PI_Control.png')

plt.show()